Robotic Arm Manipulator Mechanical Design

As a final project in my Computer Aided Design (CAD) course at UCLA, I worked with a team of four to design a robotic manipulator inspired by the flexibility and adaptability of an octopus tentacle.

Highlights

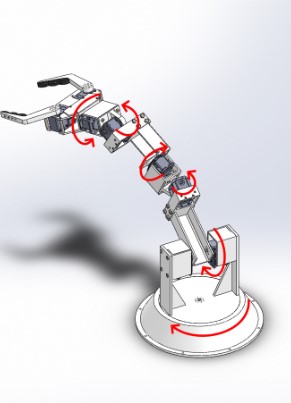

- Achieved a full 6-DOF, ball-joint-like arm using simple axial and planar joints designed in Servo-Motor CAD.

- Modular system with five subassemblies—grabber, wrist, forearm, stand, and base, mixing commercial parts and custom 3D-printed ABS.

- Engineered for easy assembly and low cost: lightweight (~3 kg), under $450 total.